Selected Research Projects

NSF PFI:AIR-TT "Innovative High-Performance Cold-Formed Steel Wall System for Light Framed Construction"

PI: Dr. Cheng Yu, UNT; Co-PI: Jeff Martin, Verco Decking Inc.

Sponsor: National Science Foundation.

Period: August 2014 - January 2016

Award Number: 1445065

Abstract:

This PFI: Accelerating Innovation Research (AIR) Technology Translation (TT) project focuses on translating a research discovery on the use of perforated corrugated steel decks as sheathing to fill the need for non-combustible high-performance shear walls for mid-rise light-framed buildings. Mid- and low-rise buildings comprise the majority of buildings in the United States. The mid-rise multi-family homes (4-9 stories) are becoming the housing trend to meet the increasing demands of population growth and urbanization. The use of cold-formed steel (CFS) would be highly cost-effective for mid-rise light-framed buildings. However the existing shear wall technologies impede the use of CFS in mid-rises due to the requirements of non-combustibility and high structural performance (shear strength, stiffness, ductility). The project will result in a prototype of the proposed non-combustible high-performance steel shear wall technology. This new technology has the following unique features: a) it uses the perforation in the sheathing as energy dissipating fuses to achieve high ductility; b) it uses the corrugation in the sheathing to achieve high strength and stiffness; c) it uses only CFS members; d) the sheathing to framing connection method is optimized for high efficiency; e) it has the same thickness as the non-shear walls; and f) it enables the engineers to control the damage locations to be away from critical building components. These features provide the following advantages over the current state-of-the-art technologies: higher structural performance, lower overall cost, non-combustibility, and controllable failure mechanism when compared to the leading competing technologies, namely the wood based panel shear wall, the steel sheet shear wall, the steel-gypsum composite panel shear wall, and the diagonal steel strap bracing shear wall in the mid-rise construction market.

This project addresses the following technology gaps as it translates from research discovery toward commercial application. It will investigate the feasibility of positioning the corrugated deck within the CFS frame in order to form standard wall thicknesses while maintaining high structural performances. A major research effort will be made to maximize the shear wall performance by developing optimal parameters in perforation, corrugation, and CFS framing details via numerical simulations and full-scale experiments. In addition, personnel involved in this project, undergraduate and graduate students, will receive innovation and technology translation experiences through modeling, building, and testing CFS shear walls. The potential economic impact is expected to be significant for the mid-rise construction industry, which will contribute to the U.S. competitiveness in building industries.

The project involves research collaboration between the University of North Texas and two industrial partners, Verco Decking Inc. and Nucor Building Systems. The industrial partners will provide deck manufacturing capacities, assist in developing an efficient connection method, and guide commercialization aspects in this technology translation effort.

NSF CAREER Award "CAREER: Comprehensive Research on Cold-Formed Steel Sheathed Shear Walls: Special Detailing, Design, and Innovation"

PI: Dr. Cheng Yu

Sponsor: National Science Foundation. NSF Program: CMMI - HAZARD MIT & STRUCTURAL ENG

Period: September 2010 - August 2015

Award Number: 0955189

Abstract:

The research objective of this Faculty Early Career Development (CAREER) project is to close the knowledge gaps about the behavior of cold-formed steel lateral force resisting systems that use shear walls sheathed with steel or wood panels. The study includes three major tasks: 1) Configuring a unique testing method designed to investigate the performance of cold-formed steel shear walls under realistic loading conditions to provide reliable experimental data to evaluate the current code prescribed shear wall strengths. 2) Based on the experimental data, establish accurate analytical models to predict the shear strength of cold-formed steel shear walls made with different sheathing materials and to provide design equations based on the principles of mechanics and mathematical models. 3) Develop advanced designs of high-performance shear wall systems with enhanced ductility and strength for low cost building constructions in seismic and strong wind zones.

The results of this research will provide simplified and improved methodologies for safe and more economical design of building structures using the cold-formed steel shear walls which are known to be recyclable and provide better fire resistance compared to wood construction. This research will also make it feasible to use the cold-formed steel walls in taller buildings than what has been possible now in seismic and high wind regions. The educational activities of the project with the developments of hands-on experiments and teaching aids and a comprehensive text book will lead to improvements in teaching about the cold-formed steel structures to both graduate and undergraduate students. This will also promote professional interest in the use of this economical and sustainable method of building construction. Graduate students will receive advanced training in research methods through their direct involvement in the project research. The research results will be disseminated through publications in professional journals and conference proceeding as well as through a project website.

Research details and progress reports are provided in the NSF-CAREER site. Link to the NSF-CAREER project website.

Performance and Detailing of Cold-Formed Steel Framed Shear Walls using Corrugated Steel Sheathing

PI: Dr. Cheng Yu

Sponsor: American Iron and Steel Institute, National Science Foundation (through CAREER award)

Period: 2008 - Present

Abstract:

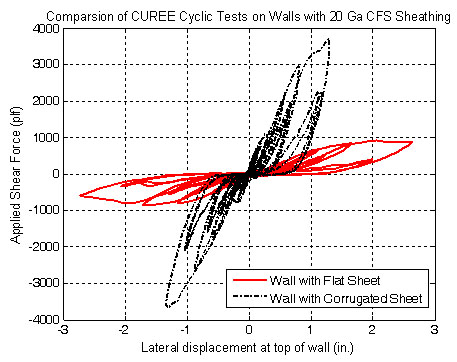

This is an ongoing project aimed at investigating the appropriate framing and sheathing details for cold-formed steel framed shear wall using corrugated steel sheathing. Initial study shows that the corrugated steel sheathing offers significantly improved stiffness and strength compared to flat sheet steel sheathing. The research continues to focus on ductility issues and seismic performance of those unconventional cold-formed steel shear walls.

CUREE Cyclic Test on a 4'x8' CFS Shear Wall using Corrugated Steel Sheathing

Steel Sheet Sheathing Options for Cold-formed Steel Framed Shear Walls Assemblies Providing Shear Resistance - Phase I and II

PI: Dr. Cheng Yu

Sponsor: American Iron and Steel Institute, Steel Stud Manufacturers Association

Period: 2007 - 2009

Abstract:

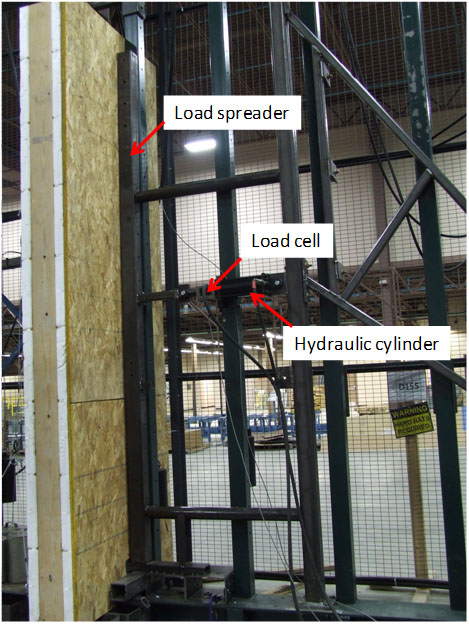

Phase I - In cold-formed steel construction, stud walls covered with steel sheet sheathing is an available option to resist lateral loads such as those caused by wind and earthquakes. The current American Iron and Steel Institute (AISI) Standard for Cold-Formed Steel Framing - Lateral Design 2004 Edition provides nominal shear strength for a limited range of steel sheet sheathed shear wall configurations. This research project was developed to add values for 0.030-in. and 0.033-in. steel sheet sheathed shear walls with 2:1 and 4:1 aspect ratios and 0.027-in. sheet steel shear walls with 2:1 aspect ratio and 6-in., 4-in., 3-in., and 2-in. fastener spacing at panel edges. For all specimen configurations, the steel sheet sheathing was installed on one face of the wall. The test program consisted of two series of shear wall tests. The first series focused on determining the nominal shear strength for wind loads for which monotonic tests in accordance with ASTM E564 standard were performed. The second series of tests addressed the nominal shear strength for seismic loads for which the reversed cyclic tests using CUREE protocol were conducted. The research was sponsored by AISI and SSMA, and was performed at University of North Texas.

Phase II - Monotonic and cyclic tests on cold-formed steel shear walls sheathed with steel sheets on one side were conducted to (1) verify the published nominal shear strength for 18-mil and 27-mil steel sheets; and (2) investigate the behavior of 6-ft. wide shear walls with multiple steel sheets. This project is the continuation of a completed project titled Steel Sheet Sheathing Options for Cold-Formed Steel Framed Shear Wall Assemblies Providing Shear Resistance by Yu (2007). This Phase 2 project confirms the discrepancy in the published nominal strength of 27-mil sheets discovered by the Phase 1 project, and proposes new values. The project also finds disagreement on the nominal strength of 18-mil sheets for seismic design, which requires further research. For the 6-ft. wide shear walls, this project indentifies special seismic detailing to prevent potential damage on studs while improving the strength and ductility of the shear walls. This report provides detailed information on the test setup, test results, and analyses.

Phase 1 report available on AISI website. link to phase 1 report.

Phase 2 report available on AISI website. link to phase 2 report.

CUREE Cyclic Test on a 6'x8' CFS Shear Wall using Steel Sheet Sheathing

Cold-formed Steel Bolted Connections using Oversized Holes without Washers - Phases I and II

PI: Dr. Cheng Yu

Sponsor: American Iron and Steel Institute, Metal Building Manufacturers Association

Period: 2007 - 2009

Abstract:

In cold-formed steel (CFS) construction, bolted connections without washers for either oversized or slotted holes may significantly expedite the installation process and lower the cost. The North American Specification for the Design of Cold-Formed Steel Structural Members requires washers to be installed in bolted connections with oversized or slotted holes. A two phase research project sponsored by American Iron and Steel Institute was recently completed at the University of North Texas (UNT) that investigated the performance and strength of bolted CFS connections with oversized and slotted holes without using washers. The bolted CFS connections were studied in a broader respect in terms of the failure mechanism, the material thickness, and the hole configurations. Combined with Phase 1 results, the Phase 2 report gives a comprehensive evaluation of the behavior and strength of bolted CFS connections with oversized and slotted holes without using washers. Revisions to the existing AISI North American Specification requirements for bolted connections are proposed to account for the reduction in the connection strength caused by the oversized and slotted hole configurations without washers.

Phase 1 report available on AISI website. link to Phase 1 report.

Phase 2 report available on AISI website. link to Phase 2 report.

Evaluation of Stiffback System for Monolithic Placement of Ecospan Joist on Insulated Concrete Form (ICF) Walls

PI: Dr. Cheng Yu

Sponsor: Nucor R & D

Period: 2008 - 2009

Abstract:

The objective of this project is to experimentally investigate the axial load bearing capacity and deflection of the cold-formed stiffback under a dead load on scaffold, a wind load, and a combination of two loads. Two stiffback thicknesses were investigated: 16 gauge and 14 gauge. The test program was focused on the stiffback with full height. However smaller height of stiffbck was also studied in this test program.

Test Apparatus

Behavior and Performance of Steel Moment Frame under Cyclic Loading

PI: Dr. Cheng Yu

Sponsor: BORM Associates.

Period: 2007 - 2008

Abstract:

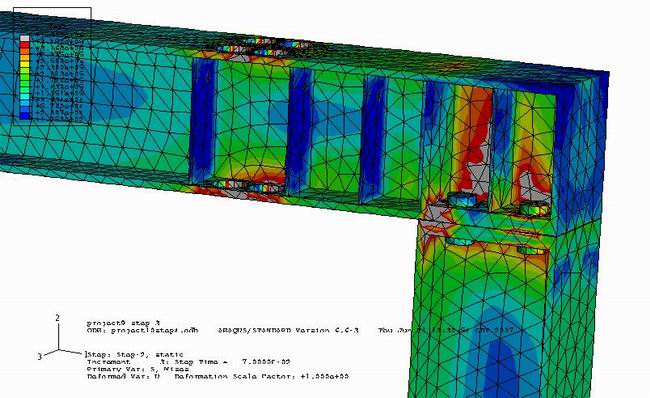

The research objective of this project is to investigate the structural performance of BORM standard moment frame under cyclic loadings (CUREE loading protocol) by the finite element method. The research results support the development of a full scale cyclic test program on those specially designed steel moment frame.

Funded Project List:

58. PI, “Behavior and Performance of Light Frame Shear Walls Sheathed by Composite Panels.” Ectek International Inc., August 2021 – November 2021, GP00101.

57. PI, “Analysis and Design of Casing Panels.” Baltimore Aircoil Company, August 2021 - March 2022, GP00098.

56. PI, “Tensile Strength of Inserts of Tiltwall Panel Lifting System.” Tiltwall Headquarters & Supplies, June 2021 - July 2021, GP00097.

55. PI, “Behavior and Performance of Screw Connection at Chord-Web Joint of Advant Trusses.” Advant Steel, LLC., June 2021 - August 2021, GP00096.

54. PI, “Experimental Investigation and Design Method of Cold-Formed Steel Joists with Edge-Stiffened Web Openings.” AISI Standards Council Small Project Fellowship Program, American Iron and Steel Institute, April 2021 - May 2022, GP00092.

53. PI, “Behavior and Performance of Light Frame Shear Walls Sheathed by Composite Panels.” Ectek International Inc., May 2021 - September 2021, GP00090.

52. PI, “Testing Special Hinge Connections.” Universal Storage Containers, October 2020 - December 2020, GP00079.

51. PI, “Testing of Cold-Formed Steel Framed Shear Walls for Frame-CAD.” FRAMECAD America, Inc., September 2020 - December 2020.

50. PI, “Analysis of Nucor Bolted Connections for Cold-Formed Steel.” Nucor Buildings Group, June 2020 – September 2020.

49. PI, “Analysis of Cold-Formed Steel Framed Shear Walls Sheathed by MegaBoard.” Ectek International Inc., June 2020 - March 2021.

48. PI, “Equivalent Section Properties of Cold-Formed Steel Members.” Hilti Inc., November 2019 - May 2020.

47. PI, “Thermal Conductivity of Cold-Formed Steel Supported Concrete Panels.” Hi-Tech Tilt, August 2019 - September 2019.

46. PI, “Testing of Cold-Formed Steel Framed Shear Walls Sheathed by Different Panel Materials.” Ectek International Inc., April 2019 - June 2019.

45. Co-PI, (Title-Removed – Export Controlled)” KRI at Northern, LLC, March 2019 – March 2020. (PI Nahotre, Co-PIs Mukherjee, Nasrazadani, Voevodin, Zhang.).

44. PI, “Shear Strength of Cold-Formed Steel Clip Angles with Multiple Lines of Screws.” AISI Standards Council Small Project Fellowship Program, American Iron and Steel Institute, April 2019 - January 2020.

43. PI, “Expanding Effective Strip Method to Thicker Stud Walls.” AISI Standards Council Small Project Fellowship Program, American Iron and Steel Institute, April 2019 - January 2020.

42. PI, “Testing of Cold-Formed Steel Member Connections Using BAC Fasteners.” Baltimore Aircoil Company, January 2019 – March 2019.

41. PI, “Testing of CF-Steel Roof and Floor Trusses.” CFS Steel LLC, October 2018 – December 2018.

40. PI, “Testing of CF-Steel Trusses.” CFS Steel LLC, April 2018 – May 2018.

39. PI, “Experimental Study on the Behavior and Strength of Lifting Lugs.” Baltimore Aircoil Company, March 2018 – May 2018.

38. PI, “Behavior and Strength of USG Structural Panel in Axial Compression.” United State Gypsum Company, March 2018 – June 2018.

37. PI, “Investigation on bolted connections in cold-formed steel members using J429 SAE bolts.” AISI Standards Council Small Project Fellowship Program, American Iron and Steel Institute, February 2018 – January 2019.

36. PI, “Testing of Cold-Formed Steel Framed Shear Walls Sheathed by USG Structural Panel Concrete Subfloor.” United State Gypsum Company, January 2018 – May 2018.

35. PI, “Testing of Cold-Formed Steel Member Connections Using BAC Fasteners.” Baltimore Aircoil Company, December 2017 – June 2018.

34. Co-PI, “Engineered Materials and Materials Design of Engineered Materials (EMMDEM); Tactical Shelters.” ARMY Natick Soldier Systems Center, October 2017 – March 2019. PI Nahotre, Co-PIs Mukherjee, Nasrazadani, Voevodin, Zhang.

33. PI, “Pull-out and Bearing Test of Screw Connections.” Noble Environmental Technologies Corporation, September 2017 – October 2017.

32. PI, “Major Improvement of LOD Specification for CFS Framing Construction.” AISI Standards Council Small Project Fellowship Program, American Iron and Steel Institute, June 2017 – March 2018.

31. Co-PI, “Light Weight Composite Structures for Advanced Tactical Shelters.” ARMY Natick Soldier System, Northeastern University, September 2016 – August 2018. PI Schultz. Co-PIs Mukherjee, Nasrazadani, Voevodin, Zhang.

30. PI, “Structural Performance of Cold-Formed Steel Framed ROK-ON Walls.” MagBoard, LLC, May 2016 – May 2017.

29. PI, “GOALI-Supplement: Achieving a Novel Cold-Formed Steel Shear Wall System from Lab to Construction Site.” National Science Foundation, August 2016 – January 2017.

28. PI, “Load Bearing Clip Angle Design – Phase Two.” American Iron and Steel Institute, March 2016 – March 2018.

27. PI, “Development of LOD Specification for Building Information Models of Metal Building Systems.” AISI Standards Council Small Project Fellowship Program, American Iron and Steel Institute, May 2016 – August 2016.

26. PI, “REU-Supplement: Deflection Characteristics of Innovative Cold-Formed Steel Shear Walls Using Corrugated Steel Sheet Sheathing.” Proposal # 1541570, National Science Foundation, August 2015 – January 2016.

25. PI, “REU-Supplement: Effect of Non-Structural Materials to the Behavior of Corrugated Steel Sheet Shear Walls.” Proposal # 1520457, National Science Foundation, May 2015 – August 2016.

24. PI, “Experimental Study on System Reliability of Cold-Formed Steel Roof Trusses.” American Iron and Steel Institute, June 2015 – May 2016.

23. PI, “Advancing Building Information Modeling (BIM) for Cold-Formed Steel Structures.” AISI Standards Council Small Project Fellowship Program, American Iron and Steel Institute, May 2015 – August 2015.

22. PI, “NSF PFI:AIR-TT Innovative High-Performance Cold-Formed Steel Walls for Light Framed Construction.” Grant # 1445065, National Science Foundation, 2014 – 2016. Co-PI Jeff Martin, Verco Decking.

21. PI, Master Research Contract with KEYMARK Enterprises, LLC, (2013 – present), total grant as of August 2015.

20. PI, “CAREER: Comprehensive Research on Cold-Formed Steel Sheathed Shear Walls: Special Detailing, Design, and Innovation.” Grant #0955189, National Science Foundation, 2010 – 2016 (NCE).

19. PI, Research Contract with FRAMECAD America, (2014).

18. PI, “Load Bearing Clip Angle Design.” American Iron and Steel Institute, September 2013 – December 2014.

17. PI, Master Research Contract with Nuconsteel Commercial Corp, (2010 – 2012).

16. PI, “Strength of Stud-to-Track Connections.” Nuconsteel Commercial Corp., June 2010 – July 2010.

15. PI, “Compression Strength of Truss Chord Members.” Nuconsteel Commercial Corp., April 2010 – June 2010.

14. PI, “Testing and Analysis of Cold-Formed Steel Structures.” Nuconsteel Commercial Corp., June 2009 – August 2009.

13. PI, “Eccentrically Loaded Cold-Formed Steel Wall Stud Walls.” Nucor Corporation, August 2008 – August 2009.

12. PI, “Evaluation of Stiffback for Monolithic Placement of Monolithic Placement of Ecospan Joist on ICF.” Nucor Corporation, August 2008 – August 2009.

11. PI, “Shear Resistance of Cold-Formed Steel Stud Walls with Wider Range of Options in Steel Sheathing - Phase Two.” American Iron and Steel Institute, August 2008 – December 2008.

10. PI, “Testing and Analysis of Cold-Formed Steel Connections with Bolts in Oversize Holes or Short Slots without Washers - Phase 2.” American Iron and Steel Institute, co-funded by Metal Building Manufacturers Association, October 2008 – September 2009.

9. PI, “Testing and Analysis of Cold-Formed Steel Structures.” Nuconsteel Commercial Corp., June 2008 – May 2009.

8. PI, “Shear Resistance of Cold-formed Steel Framed Shear Wall Assemblies for Mid-rise Construction.” Worthington Industries, February 2008 – July 2008.

7. PI, “Finite Element Analysis on Special Braced Frame.” BORM Associates, Inc., June 2007 – December 2007.

6. PI, “Testing and Analysis of Cold-Formed Steel Structures.” Nuconsteel Commercial Corp., June 2007 – May 2008.

5. PI, “Finite Element Analysis on BORM Moment Frame.” BORM Associates, Inc., April 2007 – May 2007.

4. PI, “Testing and Analysis of Cold-Formed Steel Connections with Bolts in Oversize Holes or Short Slots without Washers.” American Iron and Steel Institute, April 2007 – August 2008.

3. PI, “Shear Resistance of Cold-Formed Steel Stud Walls with Wider Range of Options in Steel Sheathing.” American Iron and Steel Institute, January 2007 – April 2007.

2. PI, “Testing and Analysis of Cold-Formed Steel Structures.” Nuconsteel Commercial Corp., June 2006 – May 2007.

1. Co-PI, “Cold-Formed Steel Structures Analysis.” Nuconsteel Commercial Corp., June 2005 – May 2006 (PI: Dr. Bill Grubbs).

See complete list of funded research projects in Dr. Yu's CV.